Escalators are essential vertical transportation systems used in malls, metro stations, airports, and large commercial complexes. Designed to move passengers safely and efficiently, they consist of numerous mechanical and electronic parts. Among these, the escalator handrail plays a vital role in both safety and passenger comfort. Without handrails, escalator use—especially for children and elderly passengers—would be unsafe and unreliable.

An escalator handrail is the moving strip of rubber or reinforced fiber installed on both sides of the escalator. It moves in sync with the steps and serves as a support for balance. Beyond its physical function, it provides passengers with confidence and trust while using the system.

The handrail acts as a dynamic support system, keeping passengers stable while the escalator is in motion. Its movement must remain perfectly synchronized with the steps; even minor speed deviations may cause hand slippage, imbalance, or accidents. This synchronization is achieved through rollers, belts, and gear mechanisms connected to the main motor, in compliance with international standards such as EN 115. During sudden stops or speed changes, the handrail helps absorb shock, much like a vibration damper, reducing the risk of falls. Correct dimensions also ensure accessibility for vulnerable groups, including seniors and children. On the other hand, surface wear or reduced friction can compromise safety—making periodic inspection and replacement essential.

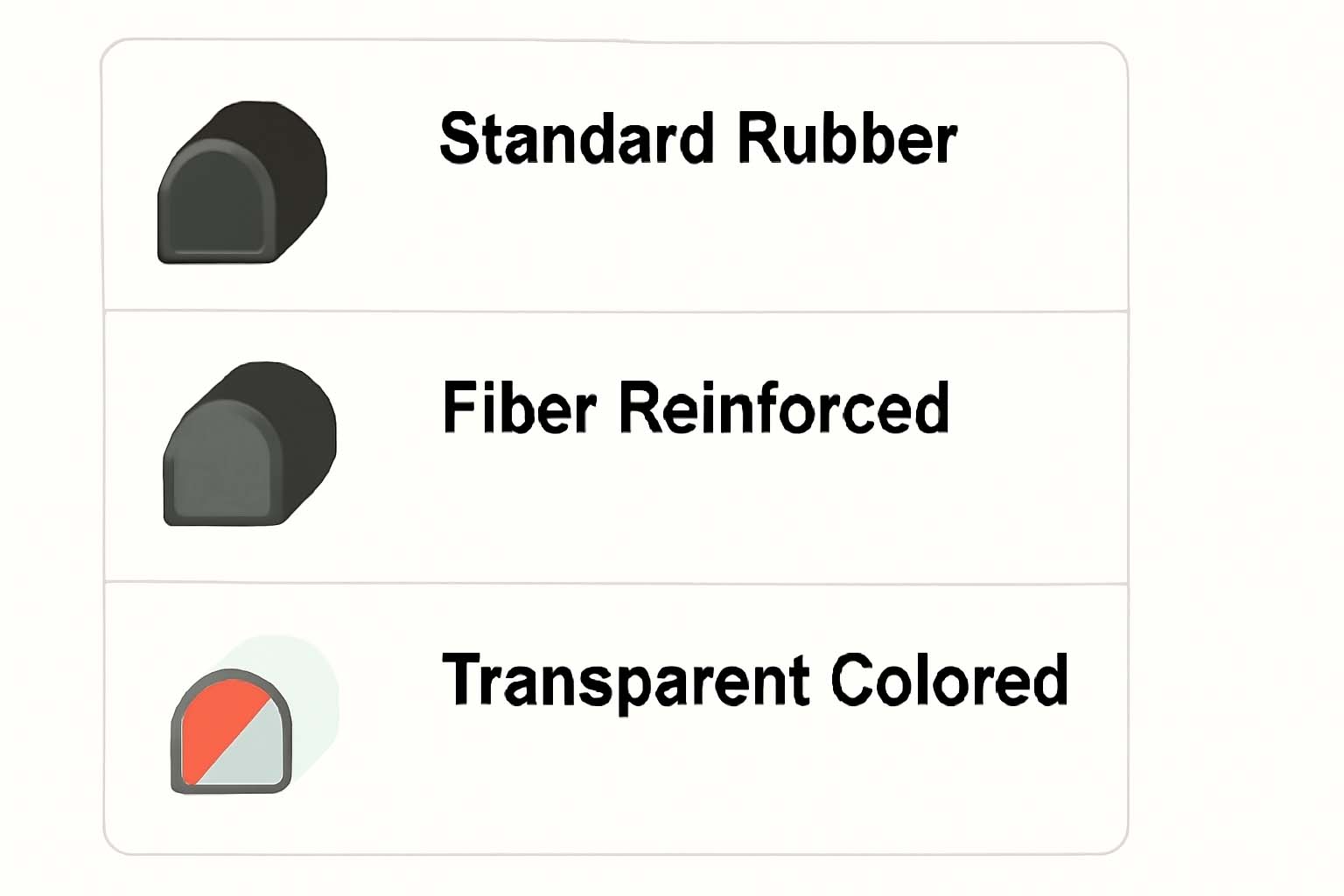

1. Standard Rubber Handrail: The most common and cost-effective option. Found in malls and office buildings, these handrails are made of durable rubber that withstands friction and daily use. They are easy to install and replace, making them ideal for projects with moderate traffic.

2. Fiber Reinforced Handrail: Built with internal fiber layers, this model is engineered for high-traffic environments like metro stations and airports. It offers higher tensile strength, reduced deformation, and long service life. Although more expensive initially, its durability helps reduce long-term maintenance costs.

3. Transparent or Colored Handrail: Used mainly in luxury projects such as hotels, premium shopping malls, and branded architectural spaces. These handrails can be customized with colors, logos, or even integrated LED lighting. Their cost is significantly higher due to complex production and design.

The price of escalator handrails depends on several variables: material quality (rubber vs. reinforced fiber), width and dimensions required by the escalator model, brand and country of origin (European and Japanese products are higher quality but more expensive), market currency fluctuations, and customization features such as colors, logos, or LED integration. Simple rubber handrails are the most affordable, while luxury customized models are the most costly.

Like other escalator spare parts, handrails require regular inspection and servicing. Signs of wear include cracks, surface tears, or discoloration. If these occur, replacement should be immediate to maintain safety. Preventive maintenance steps include:

An escalator includes complex mechanical and electronic components such as the motor, drive chain, rollers, and control systems. The handrail stands out because it directly interacts with passengers. Functionally, it acts as a safety support; visually, it contributes to the system’s overall appearance. Worn or cracked handrails not only reduce safety but also leave a negative impression of poor maintenance. For this reason, handrail replacement is a top priority during escalator overhaul projects.

The escalator handrail is one of the most critical escalator spare parts, ensuring both passenger safety and system performance. Alongside other mechanical and electronic components, it plays a central role in the escalator’s reliability. Due to frequent price fluctuations, it is recommended to contact authorized suppliers for the latest price updates and professional consultation.

For consultation and purchase of escalator handrails or other spare parts, contact LionLift.

For increased accessibility, LionLift installed durable and safe elevators at Madrid Metro's key interchange stations. MetroFlex models are ideal for urban rail environments with frequent use and minimal downtime.

This comprehensive guide explains what an escalator is, its main components, types, and how it works, along with safety tips and maintenance advice. It also introduces Lion Escalator and Lion Elevator as the official representatives of Lion Lift Europe in Iran, Oman, UAE, and Iraq, ready to supply and service escalators internationally.

Professional escalator service and maintenance: costs, steps, overhaul, and safety checklist. Extend escalator lifespan with expert care.

As one of the largest and busiest shopping destinations in Europe, Westfield London required escalators built for endurance, high-volume traffic, and energy efficiency. Our Lion UrbanMove XL series met every demand, combining smart motion control with heavy-duty mechanical reliability.

LionLift is a global manufacturer of innovative, high-performance elevator and escalator systems with international service and engineering excellence.