Escalators are widely used in shopping malls, metro stations, airports, office complexes, and even some high-traffic residential projects. Continuous operation and heavy passenger load put both mechanical parts (chains, bearings, rollers) and electrical systems (motor, gearbox, control panel, sensors) under constant stress. Therefore, escalator service is not optional but a critical requirement to ensure safety and performance stability.

Lack of service leads to friction increase, overheating of bearings, chain elongation, reduced braking force, and sensor errors. The result: sudden breakdowns, higher repair costs, and safety risks. Regular maintenance provides key benefits:

The cost depends on variables such as model, passenger capacity, environmental conditions (humidity/dust), type of service (routine or overhaul), and spare parts requirements.

Note: Regular service is usually much cheaper than emergency shutdowns and heavy repairs.

Performed during routine visits to reduce wear and ensure safety:

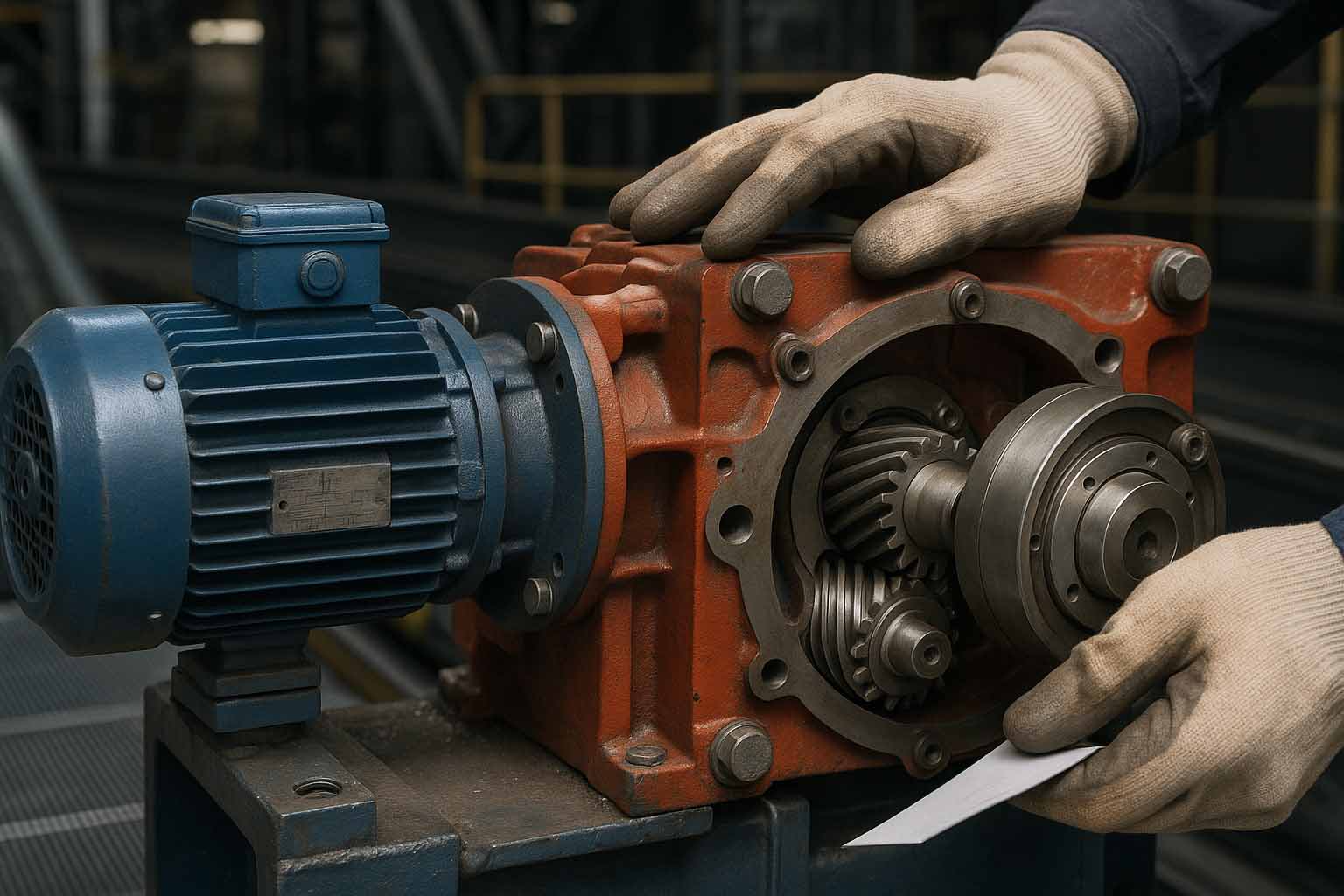

Performed by certified technicians, including detailed measurements and adjustments:

In case of abnormal wear (such as gearbox oil discoloration or bearing noise increase), corrective action is defined and recorded in the service report.

Overhaul is carried out every 3–5 years (depending on usage). It includes complete mechanical/electrical inspection, replacement of critical parts, software/drive parameter updates, and restoring performance close to new. Though costly, it is often more economical than replacing the entire system.

| Service Type | Interval | Main Actions | Benefits |

|---|---|---|---|

| Daily | Every day | Cleaning, visual check of comb/steps, start/stop verification | Prevents surface-level issues and ensures basic safety |

| Monthly | Every 30 days | Lubricating bearings/chains, emergency stop test, vibration monitoring | Reduces wear and prevents small failures |

| Quarterly | Every 3 months | Motor/gearbox/brake inspection, control panel and sensors | Ensures safety of critical components |

| Yearly | Every 12 months | Comprehensive mechanical/electrical check, replacement, calibration | Increases lifespan and reduces major failures |

| Overhaul | Every 3–5 years | Complete restoration, critical part replacement, control upgrade | Long-term reliability and near-new performance |

After each service, the following should be provided to the client:

In case of these symptoms, immediate shutdown and urgent inspection are recommended.

How often should escalators be serviced? Depends on traffic; usually monthly/quarterly with annual full service.

Does maintenance reduce energy consumption? Yes, proper lubrication and drive adjustment reduce motor load.

What is the difference between service and overhaul? Service is preventive and routine; overhaul is a full restoration with major replacements.

For consultation and cost inquiry of escalator service, contact Lion Escalator. Our technical team provides professional services in Iran, Oman, Iraq, and the UAE.

Explore the complete guide to escalator handrails: standard, fiber-reinforced, and transparent colored types. Learn about safety roles, maintenance steps, replacement costs, and professional tips from LionLift.

This prestigious project in a UNESCO World Heritage site required a tailored approach. Our escalators were engineered not only for performance, but also to preserve and respect the historical beauty of the 19th-century arcade. The integration was seamless, quiet, and visually harmonious.

This comprehensive guide helps businesses choose the right escalator for commercial spaces by focusing on safety, efficiency, and design.

Charles de Gaulle Airport partnered with Lion Escalator to streamline passenger movement across key international terminals. Our AeroMove Series escalators are designed for uninterrupted high-capacity use, ensuring a safe and fast-moving environment in one of Europe's busiest airports.

For increased accessibility, LionLift installed durable and safe elevators at Madrid Metro's key interchange stations. MetroFlex models are ideal for urban rail environments with frequent use and minimal downtime.