Escalators are one of the most widely used vertical transportation systems in shopping malls, metro stations, airports, and public buildings. Each escalator is a complex machine made up of dozens of mechanical and electrical escalator parts, all of which play a critical role in smooth performance and passenger safety. In this article, we provide an in-depth look at the main escalator components and their impact on safety and reliability.

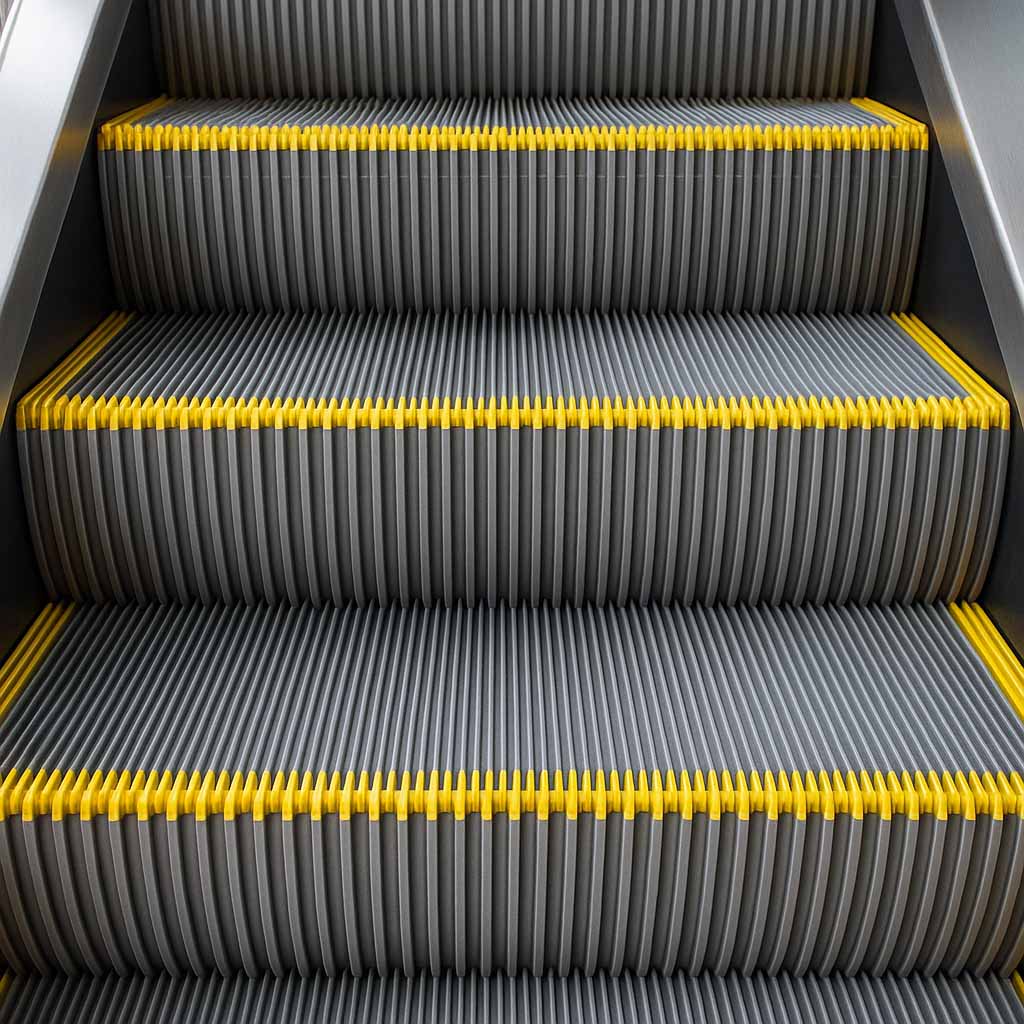

Escalator steps are usually made of die-cast aluminum or stainless steel to withstand the weight of hundreds of passengers daily. Their surfaces include anti-slip grooves to prevent skidding, especially in wet conditions. A yellow safety demarcation is often placed at the step edge to highlight boundaries between steps. Cracks, breaks, or wear can catch shoes or clothing, increasing the risk of accidents. For this reason, daily and periodic inspections of steps are essential.

The step chain is a vital mechanical component that transfers motor power to the steps. It must withstand continuous tension, pressure, and friction. Poor lubrication or chain wear can lead to sudden escalator stoppage or even step derailment, posing serious risks to passengers. Using high-quality chains and monthly servicing is critical to safety.

The drive motor is the heart of the escalator, ensuring smooth and continuous operation. It must have sufficient capacity for non-stop use in busy environments such as metro stations and airports. Many modern motors are equipped with emergency brake systems to stop the machine instantly in case of malfunction or power outage. Investing in high-quality motors improves performance and reduces future repair costs.

The handrail is the moving rubber belt that passengers hold for balance. Synchronization between the handrail and steps is vital; if speeds differ, passenger stability—particularly for children and seniors—may be compromised. Handrails are typically made from reinforced rubber or polymer compounds, resistant to stretching and tearing. Sensors are installed at entry and exit points to stop the system immediately if objects or clothing become trapped.

The brake system operates in two modes: operational brake for normal speed control, and emergency brake for sudden stops. Typically installed on the motor or gearbox, brakes must be regularly tested. Any malfunction or delay in braking can result in serious accidents, especially during peak traffic hours.

Modern escalators are equipped with smart sensors to continuously monitor system conditions:

These components are directly tied to passenger safety and must be inspected and repaired immediately if faulty.

Rails guide the movement of steps, while the truss forms the main metal framework. If rails become bent or damaged, step movement becomes noisy or unstable. The truss must be made of high-strength steel to withstand heavy loads and constant use. Proper installation of rails and truss directly impacts safety and durability.

Escalator steps are made from slip-resistant metals such as aluminum or steel, reducing the risk of slipping even in wet conditions. Meanwhile, the handrail moves in sync with the steps. According to global safety standards, the allowable speed difference between steps and handrail is less than 2%, ensuring passenger balance and minimizing accidents.

The emergency brake system is one of the most critical safety features. It activates in cases such as:

Modern brakes are electromechanical and equipped with intelligent sensors. If the step speed goes beyond safe limits, the system issues an immediate stop command—preventing group falls or serious injuries.

Parts like the comb plate and skirt panels are designed with tight safety clearances to prevent shoes, clothing, or loose objects from getting caught. Standards such as EN 115 and ASME A17.1 precisely define these gaps to ensure passenger safety.

Genuine, high-quality parts are essential for reliable operation. A weak drive motor may overheat during peak hours, while poorly maintained step chains may break or lock, causing sudden stops and accidents. Regular lubrication, heat monitoring, and emergency brake integration are strongly recommended.

Even the highest-quality escalator parts face natural wear and tear due to constant operation. Regular preventive maintenance is critical to ensuring safety and prolonging service life.

With a consistent maintenance program, not only is passenger safety improved, but repair costs are reduced and overall system lifespan is significantly extended.

Escalators are complex systems in which every component contributes directly to passenger safety. Choosing original parts, ensuring proper installation, and scheduling routine servicing are the three cornerstones of preventing accidents and extending system life. Lion Escalator, as part of LionLift Germany, supplies original escalator spare parts and provides professional maintenance services. With a specialized team and certified parts, we ensure safety and system longevity in all projects. Lion Elevator also offers international services in design, installation, and maintenance of elevators. Direct cooperation with LionLift Germany provides clients with access to the latest European technology and original spare parts.

Discover the key escalator parts, their role in passenger safety, and essential maintenance tips. Learn how steps, chains, motors, handrails, brakes, and sensors ensure reliable and safe escalator operation. Updated 2025 guide.

Designed for aesthetics and experience, our VisionCab elevators provide visibility and seamless movement in a vibrant retail environment.

Home escalators are a modern, space-saving solution that add comfort and luxury to homes, galleries, cafés, and boutique shops. With proper installation and regular maintenance, they provide long-term safety, style, and value.

The article explores the importance of escalator maintenance, overhaul, and general service, explaining how these services can extend the lifespan of the equipment and prevent sudden breakdowns. It also outlines the differences between overhaul and general service, along with safety tips and how to choose the right company for these services.

LionLift is a global manufacturer of innovative, high-performance elevator and escalator systems with international service and engineering excellence.